Make more. Waste Less.

Food & Beverage Industry Solutions

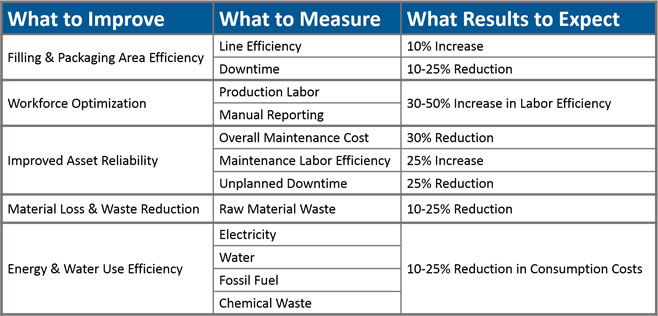

Food and beverage manufacturers constantly face challenges brought on by furious competition and slim margins. To stay profitable, leading companies are always exploring solutions to lower cost and drive operational efficiency across their operations.

For over 20 years, InSource has helped clients address the top 5 issues below:

Connect with Us

Fill out the form below to have InSource contact you to discuss food and beverage solutions.

Commonly, our food & beverage manufacturing clients to ask, why aren't my packaging lines performing to their design capacities? Specifically:

- What equipment areas are causing downtime?

- What are the root causes of those downtimes?

- What choices are operators making that lead to downtime?

Armed with the answers to these questions, our clients are making better decisions to improve performance and profitability.

Below are examples of some of the tools, approaches and best practices used to achieve results.

New Belgium Brewing Company Increases Capacity

Line Optimization: A Master Class - Rich Products

Industrial research has shown the importance of implementing structure with shift handovers in the form of structured logs and checklists. However, an estimated 80 percent of the world’s food & beverage operations still lack a structured approach to shift handovers and use paper logbooks to record critical information. This lack of structure dramatically increases the likelihood for missing critical information and misunderstandings occurring. These misunderstandings and missed information can sometimes have disastrous results.

InSource has been leading the way, in helping manufacturers improve shift handovers and optimizing workforce routines.

Mobile Operator Rounds

Shift Handover Overview

Asset Performance Management (APM) helps food and beverage manufacturers improve overall equipment effectiveness (OEE), through improved asset availability.

Improving asset reliability is one of the key areas where our clients expect to increase overall profitability. Improved performance means there will be fewer unplanned machine starts stops and better adherence to schedule. This means that quality issues from stop/start cycles are minimized, and "on time, in full" deliveries are maintained. See below for ideas on developing an APM strategy and using sensor data and the underlying conditions they communicate to reduce your unplanned downtime.

Reducing waste in all its flavors is another area where our food and beverage clients expect to increase overall profitability. Manufacturing execution systems (MES) play a key roll in tracking production and waste streams as well as improving production line availability. But ultimately, it takes a sustainable and engaged culture and the ability to connect execution data to work processes that eliminates waste. Here’s 2 videos that will give you an idea of what’s possible.

Energy cost is one of the largest operating expenses for food & beverage manufacturers. Improving your energy efficiency can result in huge savings in operating costs. Through linking energy data with production operations data, you can:

- Uncover energy-saving opportunities from operational activities

- Allocate energy consumption according to products, enabling more accurate product pricing

- Identify the most energy efficient production recipes, operations methods and human behaviors that sustain them

Watch the videos below to learn more about how you can improve energy efficiency and lower overall operating cost.

More Food and Beverage Resources

Inside Look : Take a Tour of a Real-World OEE Application

The LNS Research eBook Explains the First Steps Towards Digital Transformation

Customer Reports of Achievements Gained by Implementing MES Software

High-Efficient Flat Monitors Tailored for F&B Machine

IPPC 5211WS IP69K Video, Advantech

Dream Report Success Story: Lifeway Delivering Kefir Probiotic Products

MDT AutoSave Increases Productivity and Reduces Downtime and Safety Risks for Nestlé Purina

Large Soft Drink Manufacturer Avoids Production Downtime When PLC Code is Lost