Digitally Transform Mining Operations to Improve Profitability

Metals & Mining Industry Solutions

Digital technology can help you unite, analyze, and manage your engineering data, processes, and supply chain in an intelligent and efficient way. It can also help you operate with the highest levels of corporate social responsibility.

Discover how our solutions can remove silos, integrate your data, boost collaboration, and increase efficiency to maximize return on capital throughout your global portfolio – at all stages of the asset lifecycle.

The most pressing issues for Mining are:

- Remote Visualization

- Asset Reliability

- Process & Workforce Optimization

Learn how we can help you transform your mining organization.

Most leading mining companies have historically evolved with organizational silos, usually between mines, processing facilities and logistics. In the age of increasing automation, data, and digitalization, these silos often prevent end-to-end visibility and optimization opportunities to realize resource to market potential.

InSource can give you the ability to monitor and control the entire mining value chain, from the mine to the port, all from a remote location.

By cultivating all of this expertise in the same room, we can dramatically improve opportunities to collaborate, de-risk decisions, and place greater focus on business improvements.

Solutions

- Integrated Operations Centers

- Remote Operational control

- One Place for End-to-end control

- Operational Consistency/Safety

- Shift Handover/Electronic Logbook

- Situational Awareness

Rio Tinto - Mine of the Future

Introduction to System Platform 2017 with InTouch OMI

Beyond Traditional HMI

Roy Hill Mining Excellence From Pit to Port

Mining companies are asset-intensive businesses and have long focused on asset performance management (APM) as a core competency. According to research, 77% of mining executives are focused on cost and performance management.

APM 4.0 is a step change in the way a company conducts maintenance. Just as with Industry 4.0, APM 4.0 relies on cyber-physical systems to fundamentally change the way a business works.

With improved analysis, you’ll eliminate inefficiencies, optimize operations, and improve profitability.

Solutions

- Asset Performance Management Platform

- Condition Based Maintenance

- Predictive Asset Management

- Mobile Operator Rounds

Improve Mining Productivity with Asset Performance Management

Mobile Operator Rounds

The high cost of doing business tops the mining industry challenges. In addition to maximizing returns, companies must improve performance, efficiency, and operational effectiveness. This is only achieved by reducing commission and start up time, training operators in normal operations and high risk scenarios, and driving safety initiatives.

Workforce Optimization looks at maximizing employee productivity and efficiency through operational insight and automation.

Solutions

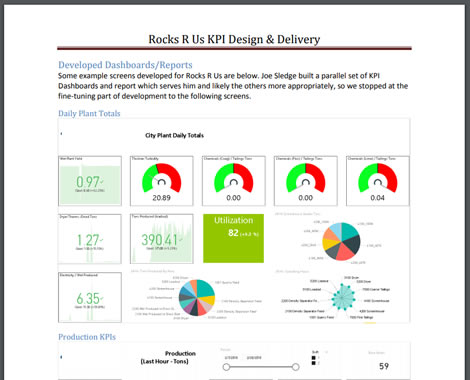

- InSource XO Downtime Tracking and OEE

- Plant Dashboards and AVEVA Insight

- Hexagon/j5 International Electronic Logbook and Shift Handover

Connect with Us

Fill out the form below to have InSource contact you to discuss metals and mining solutions.